Extrusion

We know how to handle pressure.

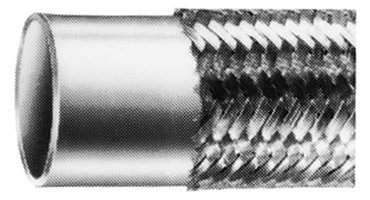

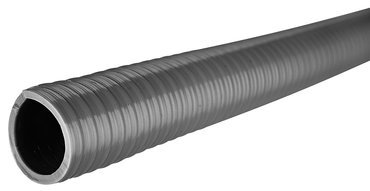

In the extrusion process, the machine continuously presses solid to viscous masses under pressure from a shaping opening. As a result, objects with the cross-section of the opening are theoretically formed in any arbitrary length. With our modern extrusion systems, we produce a wide variety of corrugated and smooth tubes in many different variations.

Whether it be special tubes or medium-conducting lines, Schlemmer produces single-layer to five-layer corrugated and smooth tubes in slit, closed or perforated versions. Our product portfolio ranges from standard products, such as our Schlemmer Gigant in nominal sizes up to 95mm, to complete customer-specific individual developments.

Variety by thermoforming

Schlemmer also offers a wide range of geometries by using modern thermoforming systems worldwide. As demanding geometries are often required, especially in the automotive industry, the automotive division at Schlemmer adapts the extruded filling tubes precisely to the limited vehicle space.

Technical specifications:

- Max. unit size: 4500x1000x1000 mm

- Heat resistance: 15 - 180°C (max. 250°C)