Customised solutions

Tailor-made and sustainable.

For our individual solutions, we bundle our core competences of different process technologies: extrusion, injection moulding, high-precision injection moulding, MuCell, thermoforming and turning. With our own tool and die-making division, we can offer you every conceivable solution. At present, we manufacture and procure more than 700 customised tools each year.

We are your solution partner. Worldwide.

We accompany many of our customers in the development process. Our certified project managers and development engineers form efficient competence teams with a high degree of maturity throughout the entire product development process. If you have any special requirements beyond the scope described here, simply contact us to find the ideal solution for your application.

Do you need your own specified product? Do not hesitate to get in touch with us.

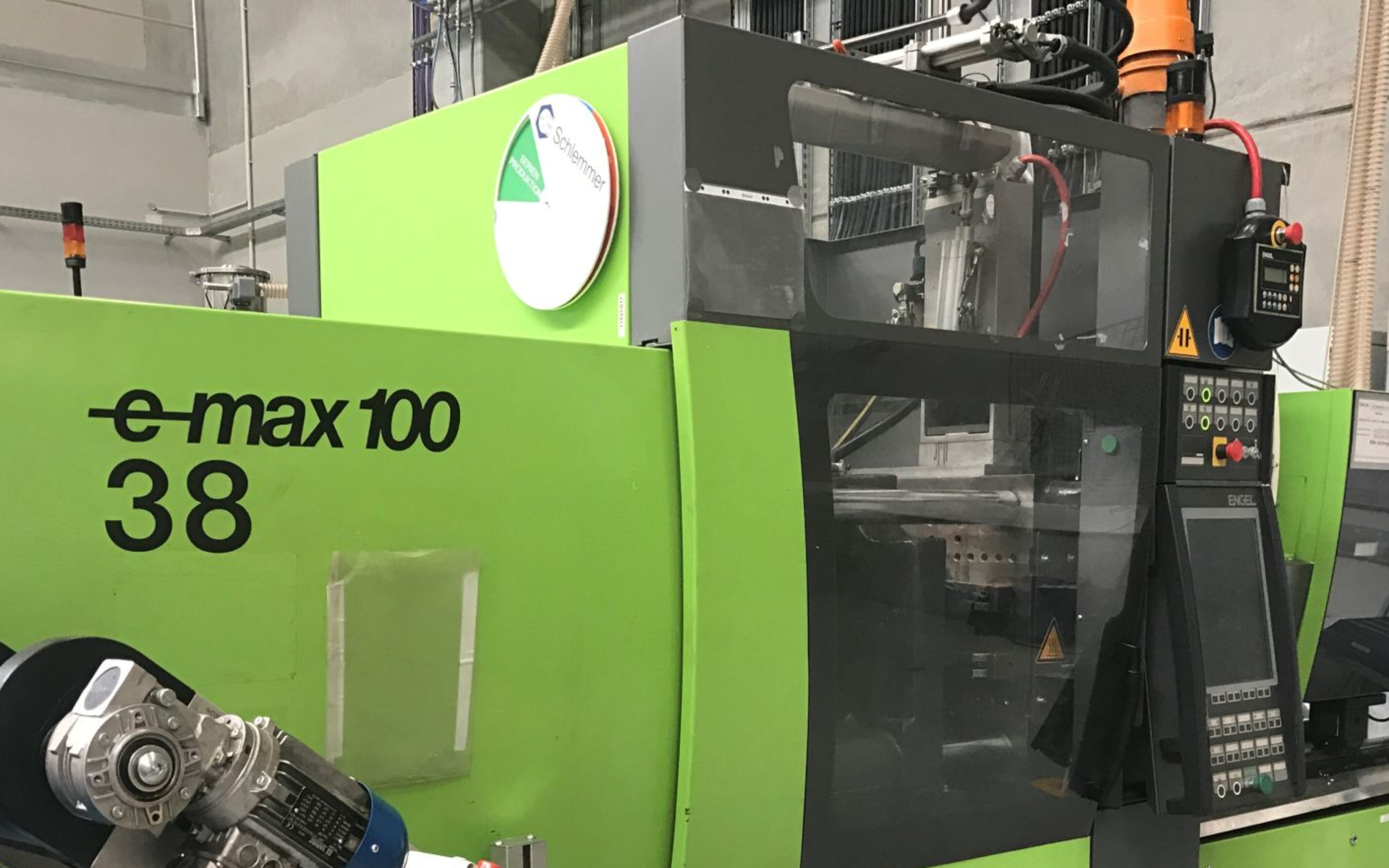

Injection moulding implemented individually .

A large portion of our customised injection moulded products is used in the automotive industry:

- cable conduits and guides

- equipment carriers

- control housings

- fuse boxes

- wiper/washer tanks

...

Just to name a few. But also in other industrial sectors, injection moulded products from our repertoire are indispensable. For example, we develop technical components for electrical tools and 2K parts, such as switch elements for forklift trucks and tractors.

Perfect match.

In addition to common injection moulding technology, Schlemmer also has special expertise in high-precision injection moulding. We can manufacture your products precisely to the μ and also process high-performance and high-temperature plastics such as PPS and PEEK. Our product solutions can later be found, for example, in fuel systems, brake systems and wiper/washer products, but also in the industrial sector. They often form the perfect symbiosis with our customer-specific Air & Fluid systems.

Air & Fluid systems according to your needs.

Our customer-specific Air & Fluid systems are mostly produced by using extrusion technology and are individually thermoformed as required. With the right connectors and attachments that are assembled directly by us, they are the perfect system for your requirements. Schlemmer Air & Fluid products are frequently used in the automotive industry. A small selection of our competences:

- fuel lines

- wiper/washer lines

- air extraction ducts

- battery degassing lines

- cooling water lines

...

Flexible and strong.

In tight and complex spaces, the focus of media-carrying systems is primarily on impermeability as well as chemical and mechanical resistance. Our wiper/washer lines are laid over very long distances in the car - from the wiper/washer tank through to the rear. Flexibility as well as absolute tightness of the tube are indispensable and therefore required. However, Schlemmer also offers this in other industrial sectors. Individual medium-conducting systems are also important in the chemicals industry, the food and beverage industry, as well as in heating and plumbing.